Trix Manufacturing (Thailand) Co.,Ltd.

Siam Trix Manufacturing Co.,Ltd.

Siam Trix Manufacturing Co.,Ltd.

-

Product Process : Pressing, Machining, Welding, Surface Treatment, Assy and Completed parts

We can support all these processes in our factory.

Our Products

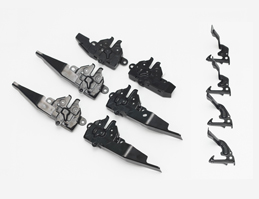

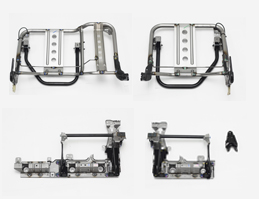

Body Assembly Parts Hood Lock, Door Lock Seat Parts for 4W

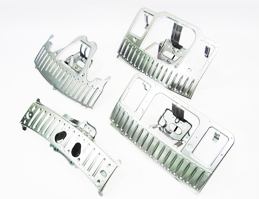

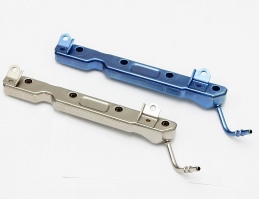

Frame Parts for 2W Engine Parts for 2W Electroless Nickel / Zinc Nickel Plating Parts

-

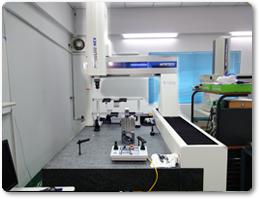

QUALITY CONTROL COORDINATE MEASURING

UNIVERSAL TEST

PROFILE PROJECTOR

X-RAY COATING THICKNESS

SALT SPRAY TEST INSTRUMENT

CHEMICAL ANALYSIS

FISCHER SCOPE

HIGH-TEMP CHAMBER

CONTRACER

SURFACE ROUGHNESS

MICRO SCOPE

MICRO HARDNESS TESTER

3 UNIT

2 UNIT

2 UNIT

2 UNIT

3 UNIT

2 UNIT

2 UNIT

1 UNIT

2 UNIT

2 UNIT

2 UNIT

2 UNIT

-

DIE : Produce a high quality die at low-cost

Challenge for making high performance die

PROGRESSIVE DIE

We respond flexibly to Progressive Die used for automotive parts which range from 80 to 300 Tons, We manufacture a high performance die in an integrated Environment where all necessary tools are equipped. And Scrap from press process are removed by using a Mechanism of machine movement of press machine are used for carrying out scrap from the process. We also correspond to any specifications and uses.

TANDEM DIE

We are capable of manufacturing single die for Automotive parts and range from 60 to 300 Tons for both sheet metal and Pipe shaped material. We have manufactured die for material that its Thickness was 12mm, and still aim at making die Which its performance is the most priority we concern

-

D I E SPARE PARTS : Delivery of high accuracy parts in a short time

2D & 3D TECHNICAL PARTS

Recently, we, to the full, use the high speed Machining Equipment、Wire Cut Machine to produce Various kind of spare parts for die Our technique of detail cutting enable us to Make stamping mark die.

-

PLATING J I G : Be able to handle various kind of shape

Challenge in manufacturing excellent JIG

SURFACE TREATMENT JIG

We manufacture hanging Rack for Zinc Plating, Zinc Nickel Plating, Cathodic Plating An Integrated system enable us to operate from Jig design to making of frame, hanging wire, and frame coating. Apart from rich lineup of general purposed jig, Also we are able to respond to a custom-made order according to customer’s uses